Supplies

- Fusion 360

- Laser Cutter (makerspace)

- 1/8″ Plywood

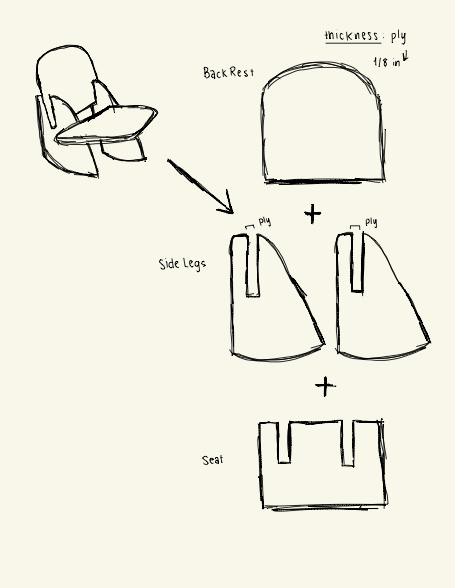

Step 1: Ideation & Sketch

The reasoning behind the decision to design a chair was because of the video where someone made a chair out of a huge number of cardboard pieces that just slide in together. I was inspired by the video; hence, I attempted to make a miniature version out of only 4 parts with plywood instead.

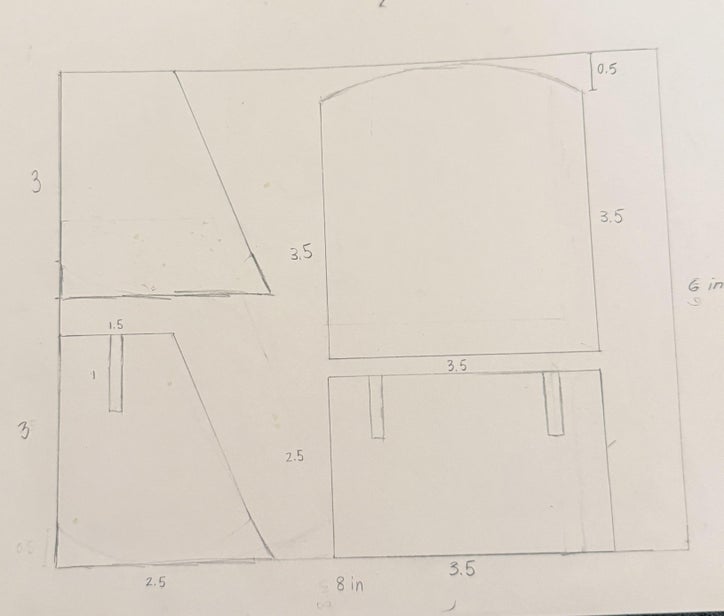

I began with a sketch of a small chair and broke it down to sketching 4 separate parts. My idea was to have a slot-based design where the seat slides into the legs horizontally, and the backrest slides vertically. I also sketched the parts on a different piece of paper and started annotating the dimensions of each part to make sure the fabrication goes smoothly later on.

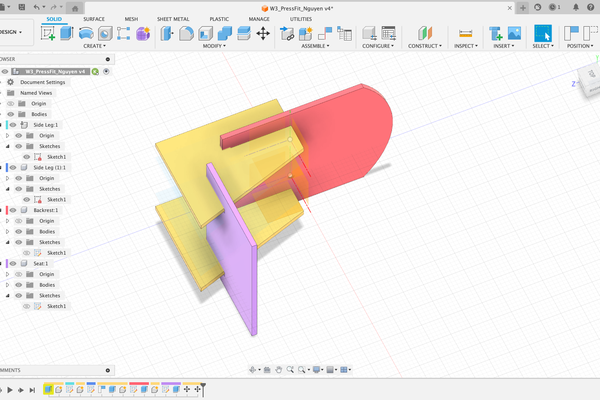

Step 2: Digital Design on Fusion

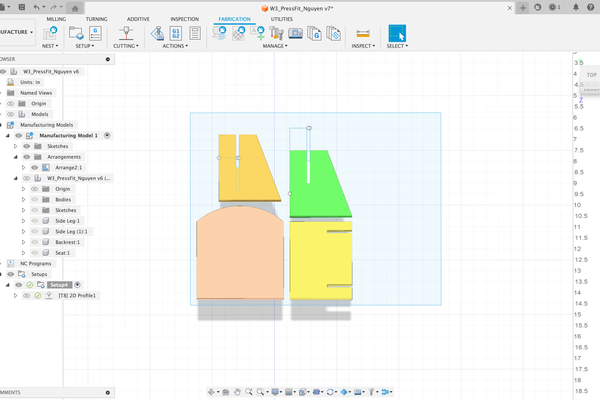

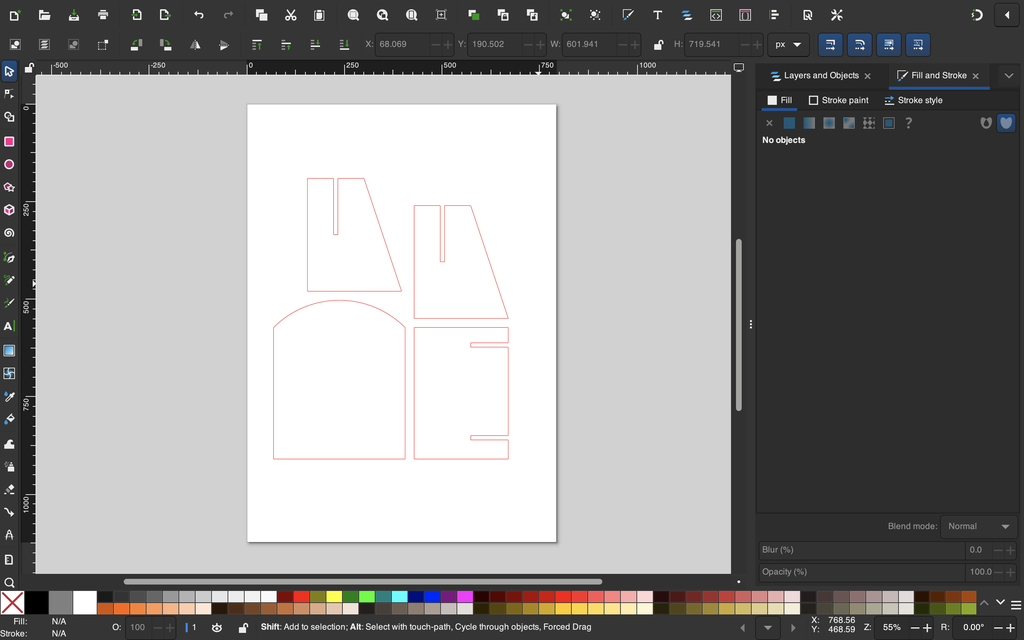

Since my design has 4 parts, I created four components: Side Leg, another Side Leg, Backrest, and Seat. Each sketch was constrained so that changes in parameters automatically updated the geometry. Then I extruded each profile to 0.125″ to match the plywood thickness. Next, I arranged all the components onto a rectangular sketch. This way, I can export the file and laser cut each part separately for later assembly.

Step 3: Export & Preparation

Using Inkscape, I transformed the DXF file into an SVG file and exported it. You can see that the cut lines are in red.

Step 4: Fabrication

I placed 1/8″ plywood in the laser cutter and uploaded the SVG file. The kerf I set up was 0.25 mm, however, the slots were slightly loose. Other than that, the fabrication process went smoothly.

Step 5: Finishing & Outcome

Assembly was straightforward. All I had to do was slide the seat horizontally at an angle into both side legs. Then, I slid the backrest vertically down into the legs. This is the final form of my press-fit miniature chair!

Step 6: Reflection

Reading Build from the Bottom Up had a significant influence on my mindset for my press-fit chair design. Usually, I build projects “top-down”: I see the end shape of the chair, then take it apart into components and force the materials into that vision. Reading disrupted this mindset by drawing out bottom-up operations, where the materials and their inherent characteristics set structure and interactions. This transferred my focus to slots, kerf dimensions, and material thickness as fluid design limitations rather than afterthoughts. Functionally, it translated into carefully adjusting slot dimensions to the extent that plywood itself dictated a snug, secure fit. Working in this manner, the chair was less about imposing an external design and more about allowing the pieces to arrange themselves into stability through press-fit joinery. This changed my own thinking regarding assembly—toward emergence, flexibility, and esteem for the creativity built into materials.